Hi Rufran,

As you suggested, here is that edited lengthy revisit of many possible angles and ramifications in such a scenario. It is a regurgitation of themes about EV, various practices and P6 failings discussed by many in the past. With a nod to nitty-gritty details of making of the sausage. All well known, but still ignored by many, with surprisingly bad practices in places where one would not expect them.

Project Lead's insistence on changing the budget in the schedule without proper rebaseline/change management will produce wrong results, that is, wrong earned value, which will produce wrong SPI, CPI, SV, CV. So, not a matter of good industry practice, but simply just producing a wrong number

Other than that budget field issue, there is more to the story when it comes to performance measurement, earned value,as you know.

In general, when you pick your P6 settings, try to pick those which will you give the most control. Hence, some of those "auto calculate" options may need to be unchecked.

Now, I will write a lot, very likely stating the obvious, and things you already know.

But, you can have better sources saying the similar. In addition to many nice AACEI materials, when it comes to the practical side of schedule resource loading and work packages, that PASEG guide by USA government is quite detailed and to the point, with practical examples. It is explained through MS Project, not P6, but the principle is the same. Just google it and download it.

Till then, here is a long one:

So,yes, say, we have produced a resource loaded baseline. Costs probably entered as units, with certain $ value per unit, say 1. With percent complete type set to "physical". And you can also have the "real" labor units, for hours of work, as you say this schedule would have it.

Some activities will not be resource/cost loaded, but are needed for proper logic structure.

If estimate is broken down by work packages and then the installation/fabrication activities, that breakdown was probably the basis for schedule structure.

If the intent is to utilize P6 earned value calculations, collection of actuals is the hard part then in the updates. But that breakdown provided by the estimate has probably helped with that, probably.... if the same hierarchy is being used for charging the hours.

But, quite likely, the level of granularity used to charge the hours of work will be much lesser than the schedule detail. Simply, say that your installation work will be shown as a distinct activity for installation of certain stretch of piping. You will have the piping quantity and the associated manhours allocated to that activity. But, it is very unlikely that anybody will put a code for that particular spool in their timesheet.

At best, the timesheet you will give you somebody's trade/discipline, and perhaps work package number.

And that is the level of your schedule hierarchy where your actuals can meet with budgeted and earned.

Here, people resort to WBS Summary type of activities or even try to use hammocks/LOE types as containers of actual cost, while activities below them bring their budget and earned values.

And then EV key indicators can be calculated at P6 WBS Level for that work package, not lower.

Often, people utilize other tools to perform calculations of EV indicators, with better control of calculations than in quirky P6. Where they just utilize P6 to produce time distributed data. Power BI has been tool of choice in this decade for many.

Either as csv exports/reports from P6, or with Power BI link to P6 database (which is harder to prepare, but it is faster later on) where you need to have the IT people involved.

Note, in an environment with inconsistent change management (frequent changes without formal re-baseline), if you want to use P6 EV calculations, you have to maintain a version of your baseline schedule which will have all those changes, such as additions or deletions of resource/cost loaded activities, or transferring $ and mh between activities. Then, you assign such schedule as a baseline for your P6 EV calculations and S-curves. It is not the one to be used for critical path analysis.

(You have the original one and the updates for critical path analyses.)

Transferring $/mh is simple. Adding activities is different You have to enter these new resource/cost loaded ones with constraints just to place them in the right spot (start and finish dates)on the timeline when they were first added to the schedule. Say you enter the "must start" start constraint, and the duration which will bring it to the finish date it had when it was first added to the schedule.

Seems complicated, but, if the changes are not shown in the baseline used for EV calculations, you will have mismatches.

Say, new activity will have $1000 (or mh) You complete it 100%, $1000 earned, right? Nope, because baseline says that there was nothing to earn to start with. $0 earned. Your CPI and SPI will not know about it.

Or, the other way around, a deleted activity. Dollars in the baseline, which can never be earned in rhe update where it does not exist.

Same about resource/cost transfers where activities still exist, but have had more or less dollars in the baseline. EV indicators are distorted again.

I covered a lot, just in case, to reduce back and forth. At least some bits could be of some use.

PASEG, again. And there are good EVM presentations (pdf formats) on internet, by various EIA748 experts. Plus DOE's very detailed training videos for every step of 748-aligned processes.

Principles are transferable to non-DOE and non-748 environments.

Best regards,

------------------------------

Boris Konrad

CCP, PSP, PMP, PMI-SP, PE

United States

------------------------------

Original Message:

Sent: 09-03-2025 04:57 PM

From: Rufran Frago

Subject: Updating Progress on Resource-loaded Schedule (What is the right method?)

Dear Boris, I appreciate your reply. As usual, very comprehensive.

Before I comment on your really insightful take, let me add context to the situation. It might not change your assessment, but we'll see. Here goes.

The Budget Units are derived from a detailed estimating process that ties labor hours directly to construction deliverables-such as pipe spools, equipment, and structural components-using an Excel-based database. Each Installation Work Package is built from the ground up, with traceable labor allocations per discipline and crew size. In this sense, the Budget Units are not abstract-they are tightly linked to physical progress.

Given that, I fully agree with your recommendation to rely on baselines for performance tracking rather than manipulating Budget fields. Your point about understanding how P6 calculates % complete-especially the differences between cost and unit-based metrics-is well taken.

Ah, yes! Memento mori, your gentle reminder that even our schedules, like all things, are fleeting! Fortunately, while life may be finite, the lessons we extract from P6 quirks seem to be eternal...ha ha ha.

I believe the core question becomes:

Which P6 progressing method is most appropriate in this scenario-the Project Lead's approach, the Senior Scheduler's, or perhaps a third option?

Thanks again for sharing your wisdom. It's always a pleasure learning from someone who's wrestled with the hornet's nest and lived to tell the tale.

RCF

------------------------------

Rufran Frago P. Eng. PMP PMI-RMP

Founder/Business and Project Consultant

Calgary AB

Original Message:

Sent: 09-03-2025 03:05 PM

From: Boris Konrad

Subject: Updating Progress on Resource-loaded Schedule (What is the right method?)

Hi, a reply in a hurry, with apologies for errors.

This exercise opens quite a can of worms, or hornet's nest, a.k.a P6. Too much to write about, as many books can

My attempt is below.

Introduction:

a) It would be good to define all the purposes of this schedule, as well as all the parties which will utilize it.

b) all the desired P6 settings have to be ascertained: Admin/Earned Value (utilizing At Completion or Budgeted, Planned or Current Dates), and then, at project level, Settings (pick the baseline to use) and Calculations. Once that context has been set, proceed to look at the rest

a. Bear P6 planned dates in mind.

c) Notes regarding the P6 context, P6 terminology/field naming, can sometimes be confusing if the very words are taken for what they sound like (e.g. "Scheduled Date").

i) e.g. variance is calculated as the difference between Budgeted Labor Units and the baseline's Budgeted Labor Units (BL Project Labor Units). But, see what value shows up under BL Project Labor Units. It will match what is under baseline project's At Completion Labor Units, not the baseline project's Budgeted Labor Units. Those two values are not likely to end up being different when it comes to the original baseline, but, when it comes to subsequent updates, those could differ, since maintenance of At Completion values sometimes escapes attention.

So, if there is a need to match At Completion and the Budgeted, it may be the other way around, where the schedulers want to check whether At Completion values still match the original budget values. But, that may be relevant for purposes other than those in your exercise.

ii) In line with the settings from "a" above, and the duplicated confusing P6 terminology, note the "Estimate at Completion-Labor Units" from "Earned Value" group, and the "At Completion Labor Units" from "Units" group of fields. Latter can be entered/plugged in. The former is calculated.

Also, the "Budget At Completion (BAC) Labor Units" from "Earned Value" group and At Completion Labor Units or Budgeted Labor Units. See which one are only calculated and which ones can be plugged in.

Your exercise points:

1) 1) Is this hypothetical Lead correct? Well, how about 50-50 for start, but then down to zero?

Yes, the baseline holds the original values. And, yes, the earned value is calculated against whatever was in a selected baseline (calculation subject to settings). But, then look under 2 below.

And another but, why would the budgeted values in the current updates need to be changed to match the At-completion values, if there were no formal changes of project budget and there was no re-baselining. Lead would need to be reminded that At Completion can as well can have prefix "Estimated", as its counterpart is named in the Earned Value group of fields. Not a budget (yet), but an estimate, a forecast.

2) 2) History: changing the project budget without formal change process is not going to show the true history of the project.

Progress tracking/Earned value metrics:

Changing the budget value will also reflect on progress tracking.

E.g. for an activity, the same percentage of completion multiplied by, say, increased budget value, will then produce a higher earned value, which will then be compared to a baseline's scheduled earned value based on a smaller number for the same percentage.

3) 3) "Industry best practices" is a volatile term, subject to local fiefdom rulers. Per Mel Brooks "It is good to be a king".

But, I would dare to say that changing budgets without formal change process is a big no-no everywhere.

The scenario's company may have different purposes for the schedule, and one has to know which other parties will utilize it. Who knows, there may be some higher wisdom behind.

Though many companies do follow very confidently the same wrong path for decades.

E.g. just recently had one which produced earned value reports, but with actuals always being the same as earned (just multiplied budget and percentage of completion). They produced CPIs different than one, but only because they have also been deleting cost loaded activities and shifting costs between activities. Sure that SPI was also wrong.

They have not noticed, the owner's controller did not notice, for three years. And there was just a simple question to be asked "How do you get your actuals?". All with 15 to 20 years of experience. Memento mori.

4) 4) Comparison is provided in all of the points above. Briefly: Lead is wrong, Scheduler is right, Project Controls Manager absent.

------------------------------

Boris Konrad

CCP, PSP, PMP, PMI-SP, PE

United States

Original Message:

Sent: 09-02-2025 10:32 AM

From: Rufran Frago

Subject: Updating Progress on Resource-loaded Schedule (What is the right method?)

PROJECT SITUATION:

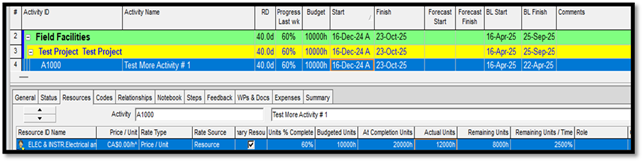

The Project Lead has instructed all schedulers to align the Budget Units in Primavera P6 with the At Completion Labor Units, stating that it's a straightforward adjustment. He also emphasized that if these two fields don't align, the overall Units % Complete will be wrong and skewed. He directed everyone to apply this approach to all resource-loaded activities in the schedule.

However, our Senior Scheduler raised concerns that this method could compromise the integrity of the project's progress history and performance metrics-especially for started activities where the Estimate at Completion (EAC) hours has changed and differ significantly from the original Budget Units.

Example 1:

- Original Budget (Budget Units): 10,000 hours

- At Completion Labor Units: 20,000 hours

- Activity has started and 12,000 hours actual spent

- The Project Lead wants to update the Budget Units to 20,000 hours to "align the budget to the most current estimate." He said that the saved static baseline assigned to the current schedule has the Budget information already and is available anytime for comparison. There's no way the project will lose the original budget information.

- The Senior Scheduler argued that without a formal scope change, this adjustment would misrepresent progress and violate standard Earned Value Management (EVM) practices. He emphasized that best practice is to preserve the original Budget Units, report variances transparently, and escalate only when deviations affect scope, cost, or schedule at the project level.

Example 2:

- Original Budget (Budget Units): 2,500 hours

- Most Current Estimate: 2,000 hours

- Activity has not started. No formalized change or scope change is approved. It was an adjusted estimate. No details provided.

- The Project Lead instructed that the Budget Units be adjusted to 2,000 hours to match the At Completion Units. He added that if an activity has not started, the Current Estimate shall automatically become the Budget Unit for perfect alignment.

- Again, the Senior Scheduler contended that this compromises traceability, reliability, and accountability. He said that once the activity starts, we can update the remaining units and the at completion hours will automatically be updated, and the budget units remains the same for comparison.

Despite these concerns, the Project Lead insisted, and the Senior Scheduler was directed to proceed. The Project Controls Manager has not commented on the situation and has not provided a specific direction. Given that, the Project Lead prevailed.

Given this situation, I'd appreciate your expert opinion on the following:

- Are there risks and implications of aligning Budget Units with At Completion or Actual Labor Units across all resource-loaded activities as prescribed by the Project Lead? Is he correct in his approach. If yes, please explain why. If not, kindly explain as well.

- How does this affect the reliability of progress tracking, historical data, and earned value metrics? Does the Senior Scheduler have a point in pushing back?

- What approach is more aligned with industry best practices, and why?

- If you can, please compare the method espoused by the Project lead and contrast it with that of the Senior Scheduler.

I am excited to read your views on this matter. As usual, thank you all and more success to AACEI.

<<Disclaimer: The situation presented is a work of fiction. Any resemblance to actual events, people, or places-living or dead-is purely coincidental. The roles, characters and situations depicted are entirely imaginary and not based on specific real-life individuals or occurrences.>>

RUFRAN

------------------------------

Rufran Frago P. Eng. PMP PMI-RMP

Founder/Business and Project Consultant

Calgary AB

------------------------------